- Home /

- Flashforge

Shop Now

- AJS Tool kits

- 3D Jewellery CAD Software

- Balances

- Beading

- Benches, Tools & Accessories

- Books, DVDs & Templates

- Burs & Drills

- Casting, Melting & Waxes

- Chains

- Cleaning

- Curing Units

-

Display

- Acrylic Props, Busts & Boards - Black

- Acrylic Props, Busts & Boards - Clear

- Acrylic Props, Busts & Boards - Frosted

- Cases, Trays & Tray Inserts

- Jewellery Rolls

- Leatherette Props, Busts & Boards - Black

- Leatherette Props, Busts & Boards - Cream

- Leatherette Props, Busts & Boards - White

- Price Labels, Tags

- Monthly Specials

- Clearance

- Dust Collection & Air Filtration Supplies

- Enamelling

-

FINDINGS - PEEKAYS

- Albert Swivel Clasps

- Bails

- Base Metal Findings

- Bayonet, Pendants & Other Fittings

- Bolt Rings

- Brooch Fittings

- Butterfly Earring Backs

- Chain Clasps - Parrot, Cartier, Lobster, Triggers

- Chain End Final/Caps

- Charms

- Cufflink Fittings

- Ear Clips

- Earring Fittings

- Jump Rings, Split Rings, Link Locks

- Pearl Fittings, Clasps, Enhancers & Beads

- Ring Clips

- Ring Settings

- Shepherd Hooks

- Sleepers

- Monthly Specials

- Clearance

- Flex Shafts & Micromotors

- Forming

- Gemmological

- Gemstones

- Gift Voucher

- Lapidary

- Lighting & Photography

- Magnifiers

- Mass Finishing

- Measuring: Gauges, Scales

- Metal: Sheet, Wire, Tube, Testing

- Microscopes

- Permanent Jewellery

- Plating, Colouring & Patinas

- Polishing & Abrasives

- Presentation Packaging

- Safety

- Sandblasting

- Setting & Engraving

- Soldering & Welding

- Stamping

-

Watchmakers

- Batteries

- Case Seals

- Clock Inserts & Movements

- Clock Parts, Keys & Pocket Watch Keys

- General Watch Tools

- Glass Fitting Tools

- Watch Band Tools

- Watch Bands & Clasps - Assorted

- Watch Bands & Clasps - Rochet

- Watch Crowns & Stems

- Watch Glasses

- Watch Movements

- Watch Parts

- Watch Screwdrivers

- Watch/Clock Cleaning & Testing

- Clearance

- 3D Printing

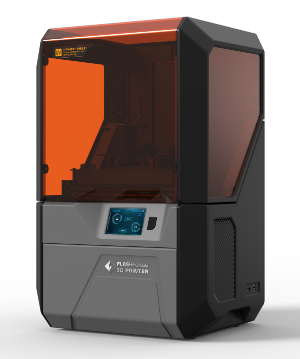

Flashforge Hunter 3D Printer

3D Printers in the Jewellery Industry

- 3D printing allows both the designer and customer to visualise the piece before it goes through the expense of manufacturing.

- It can be modelled in various compounds to simulate the colour of the end material and alterations can be made rapidly and reprinted for verification .

- Once the design is finalised, 3D printing allows you to create castable models without the need for mould creation. These models can be “resized” before printing to minimise resizing post production saving time and material, and labour cost.

- Very easy to upscale production as multiple copies can be printed at once.

- Removing the need for moulds means no wax injector, no vulcanizer, no vulcanizing rubbers.

FEATURES

- Digital Light Processing 3D Printer.

- Uses a proprietary light engine with a FHD 1080p resolution and a 50,000 hour lifespan.

- Advanced architecture mainboard works seamlessly with the light engine.

- Dual-core 800MHz ARM processor maintains high performance.

- The linear motion guide actuator along the Z axis is an industrial actuator module from Japan, giving smooth printer surfaces.

- The resin tank is made from durable aluminium requiring no maintenance.

SPECIFICATIONS

- Build Volume: 120mmx 67.5mm x 150mm

- Pixel Size X,Y: 62.5 microns (0.0025")

- Layer Resolution: 25/50 microns (0.001"/0.002")

- Light Source: 405nm LED

- File Input: STL

- Machine Size: 360mm x 310mm x 565mm

- Weight: 17.8kg

- Power: 100-240V, 50-60Hz, 1A

- Software: Flashprint

- USB Stick / USB Cable / Wi-Fi

"How to Get Started in 3D Printing" ...

Click here to download the PDF version of the AJS Guide: 'How to Get Started in 3D Printing'.

Click here for more information.